Mekong Flour Mills Ltd, is one of the major wheat flour processing companies in Vietnam, with its factory located in Phu My 1 Industrial Zone, Ba Ria – Vung Tau Province, with a milling capacity of 1200 tons of wheat per day.

Established on June 30, 2000, Mekong flour Mills, Ltd. is a 100% foreign-invested company under the Malayan Flour Mill Berhad (MFMB) group, a pioneering flour processing conglomerate in Malaysia since the 1960s. In addition to Mekong flour Mills, Ltd., MFMB previously had a large wheat flour processing plant in northern Vietnam, Vimaflour Ltd, as a joint venture between MFMB and Northern Food Corporation – Vinafood 1.

As a member of the Malayan Flour Mills Berhad group, Mekong flour Mills, Ltd. inherits over 60 years of experience in milling and a robust sourcing system from the most reputable wheat-producing countries in the world. We take pride in being a reliable partner for customers in industries using wheat flour, providing stable product quality while always prioritizing customer satisfaction in all our production and business activities.

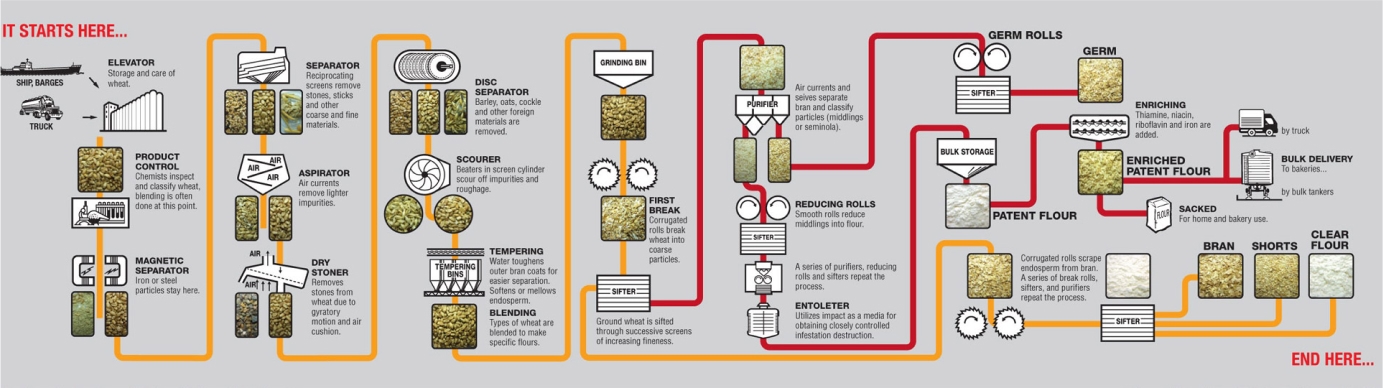

Our products are manufactured on modern production lines, applying a quality control system throughout the process, with Total Quality Management (TQM) implemented to ensure quality control, compliance with food safety and hygiene standards, and adherence to standards such as FSSC 22000, ISO 9001-2015, and Halal.

Currently, the company is a supplier of over 70 types of wheat flour products to major customers in various baking industries, including bread, pastries, Vietnamese bread, instant noodles, fresh noodles, dry noodles, sponge cakes, and snacks. Additionally, we offer specialized products for steamed buns, mantou, dim sum, bánh Pia, vegetarian products, semolina, Atta, whole wheat flour, and custom products for coated flour and tempura flour production. Furthermore, our product lines meet strict requirements for protein content and microbiological criteria for the animal husbandry, aquaculture, and other industrial sectors that use wheat-derived raw materials, such as starch, gluten, and wheat germ.